Optimize Your Devices Using Membrane Switch for Greater Efficiency

Discover the Versatile Use Membrane Switch Over in Modern Electronic Devices

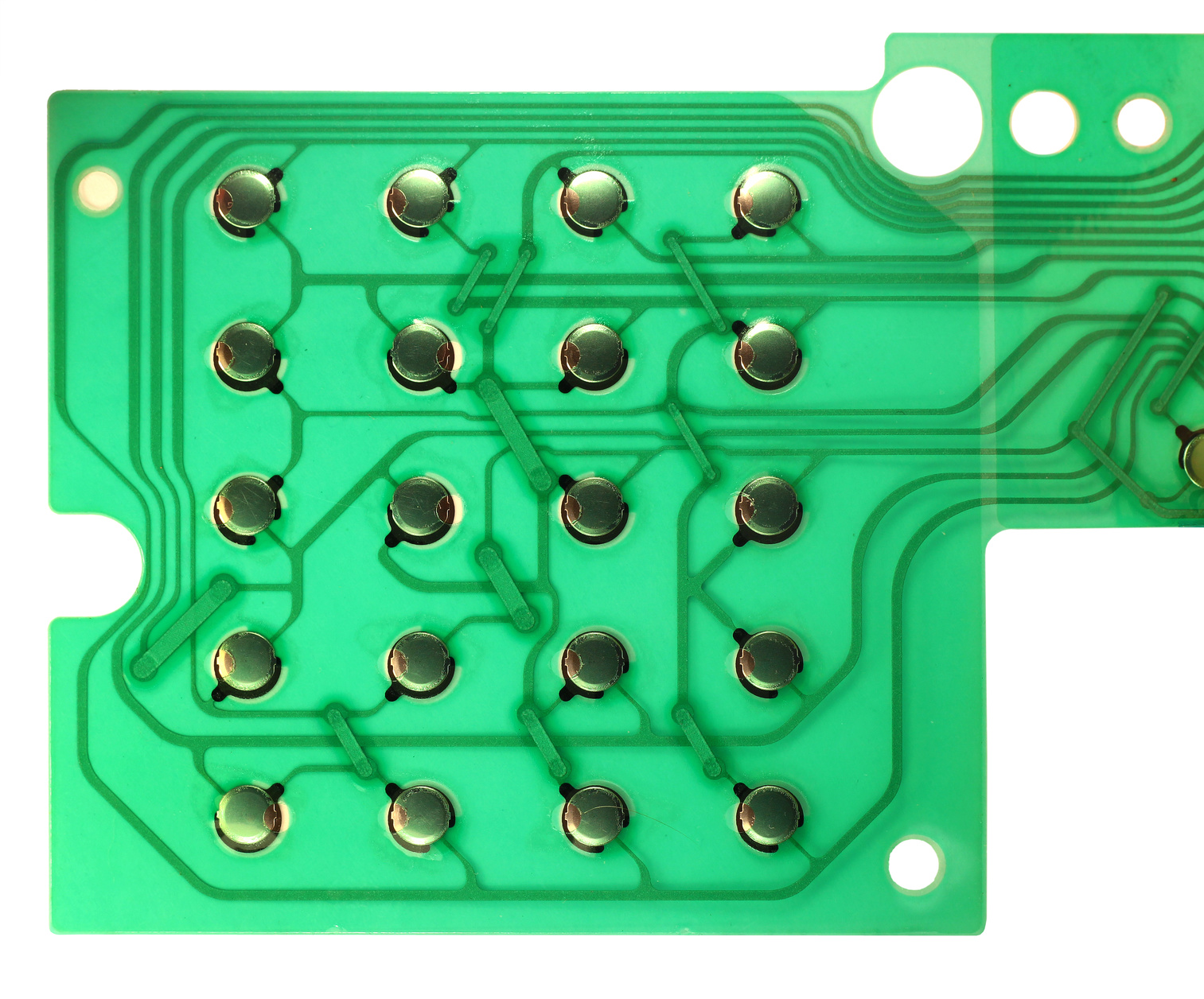

In the world of modern electronics, the application of membrane switches is extremely extensive, extending from streamlined customer gadgets to critical clinical tools. As industries continue to advance, the assimilation of membrane buttons in tools layout is essential, promising not just to fulfill yet go beyond the extensive demands of both capability and visual charm.

Discovering the Duty of Membrane Layer Changes in Consumer Electronics

Why are membrane switches so prevalent in customer electronic devices? Membrane switches are affordable to make, making them an eye-catching option for high-volume manufacturing typical in consumer electronics.

Furthermore, these switches are understood for their longevity and low maintenance. They are resistant to dirt, dust, and wetness, which improves the durability of the electronic devices they are made use of in. This reliability is vital in everyday customer items that go through regular use. Additionally, their versatility in layout enables customization in aesthetic appeals and functionality, dealing with the details demands of various digital gadgets. From microwave to push-button controls, membrane buttons supply a useful, user-friendly user interface that sustains the dynamic nature of customer electronic devices.

Membrane Layer Switches in Medical Tools: Enhancing Interface

Membrane buttons likewise play a substantial function in the realm of medical gadgets, where they enhance user interfaces with their unique advantages. These switches are particularly valued for their integrity and ease of cleanliness, crucial in health care settings where sanitation is vital. The smooth, sealed surface area of membrane layer changes enables easy sanitation, minimizing the risk of contamination and spread of virus. Moreover, their design adaptability fits the aesthetic and ergonomic demands of medical equipment, making devices extra intuitive and easily accessible for healthcare experts.

Membrane layer buttons also add to the durability of medical tools. Their resistance to fluids and pollutants makes sure that essential tools stays operational in various professional setups, including surgeries where direct exposure to liquids is typical. This resilience, coupled with responsive comments and low-profile layout, makes membrane changes an important element in improving the performance and security of medical gadget interfaces.

The Influence of Membrane Changes on Industrial Equipment Style

In the realm of commercial equipment style, the incorporation of membrane buttons has marked a substantial evolution. These buttons have transformed just how makers approach interface performances, supplying a blend of longevity and flexibility that is crucial in extreme settings. The slim account of membrane changes permits even more compact device styles, home while their resistance to dirt, water, and chemical impurities makes them perfect for industrial settings. This versatility has actually promoted the development of equipment that is not only much more durable yet additionally easier to maintain and clean, thus decreasing downtime and functional expenses.

Moreover, the customizability of membrane layer changes allows designers to integrate specific tactile responses and visual overlays that improve the individual experience and rise performance. This combination sustains drivers in accomplishing precision control over intricate equipment. The overall influence is a substantial enhancement in the functionality, reliability, and user-friendliness of commercial devices, aligning with the increasing needs for technological improvement and operational efficiency in contemporary industries.

Verdict

Membrane switches have actually changed modern electronics, providing streamlined, durable, and adjustable user interfaces across various markets. This modern technology not only satisfies the demanding conditions of different areas yet also considerably enhances customer experience, making membrane layer switches over a keystone of contemporary electronic style.

In the realm of modern-day electronic devices, the application of membrane layer buttons is incredibly considerable, spanning from sleek consumer devices to published here important clinical tools.Why are membrane layer switches over so common in customer electronics? Membrane layer buttons are cost-efficient to make, try this website making them an eye-catching option for high-volume production common in customer electronic devices. From microwave stoves to remote controls, membrane switches provide a functional, easy to use user interface that supports the dynamic nature of consumer electronics.